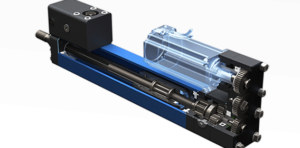

While ball screws and ball screw linear actuators are commonly used for precise linear motion, similar looking roller screws and roller screw linear actuators can provide many advantages over them to improve life, increase speed, provide more rigidity and shock tolerance, or reduce the footprint of the actuator.

Load and Life

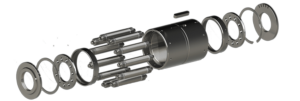

Due to the increase in the number of thread contact points compared to ball screws, a result of a satellite roller design as opposed to recirculating balls, roller screws have two to three times the dynamic load capacity and up to three times the static load capacity, in the same physical space. This translates to approximately 15-25 times longer lifespan when using a similar frame size. Or you can select a much smaller roller screw actuator to get similar performance in a space saving envelope size.

Speed and Acceleration

Because there are no recirculating ball bearings to limit velocity from friction and sliding, roller screws can handle double the rotational speeds of ball screws. This allows quicker acceleration and faster linear speeds.

Rigidity and Shock Tolerance

The increased number of contact points also enable a roller screw mechanism to be up to three times more rigid than ball screws and tolerate shock loads much better without thread damage.

Because of the complexity of design, roller screws can be more expensive than ball screws of similar sizes. But when improved performance is required over an alternative ball screw, they can provide exceptional value.

Creative Motion Control (CMC) is the technology leader in roller screw actuator design. They offer more and larger sizes and higher force/density capacities, in the parallel design, than any other manufacturer. You can see their entire lineup and a complete list of their features, benefits, and specifications at http://www.creativemotioncontrol.com.